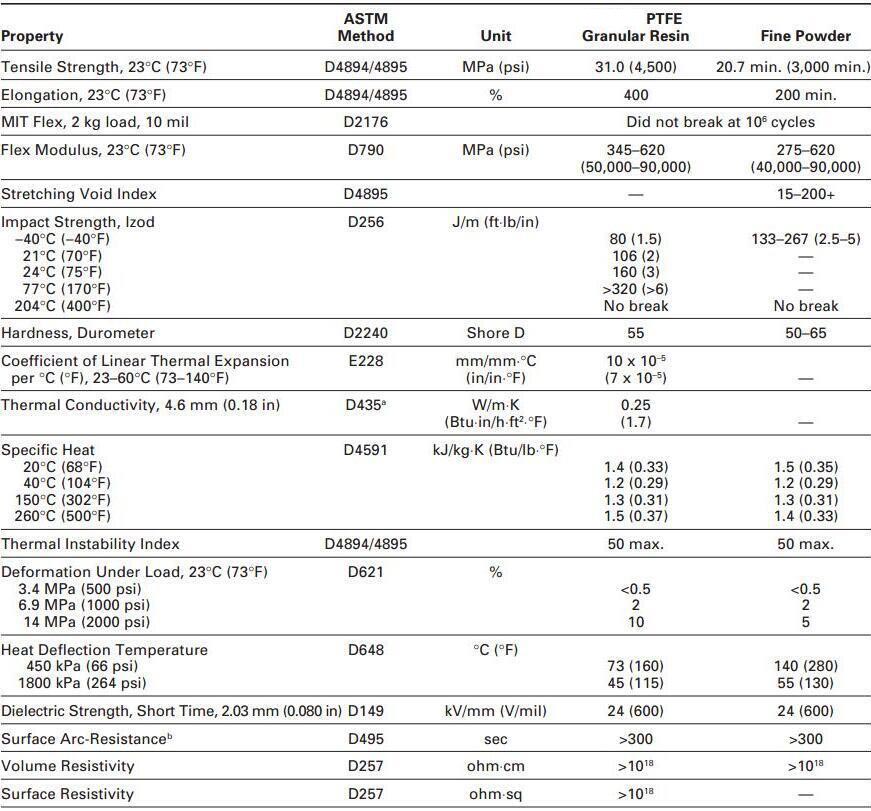

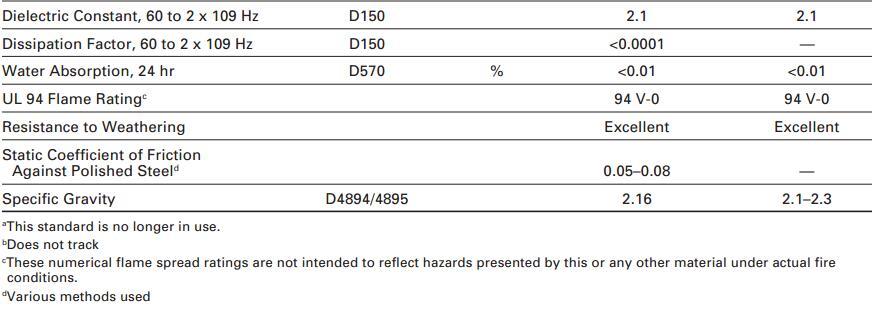

( see also polymer® PTFE and polymer® FEP & PFA Specifications ) PTFE’s mechanical properties are low compared to other plastics, but its properties remain at a useful level over a wide temperature range of of -100°F to +400°F (-73°C to 204°C).

Typical Properties of polymer® PTFE Fluoropolymer Resins

Temperature resistance

Temperatures above 77°C are not favorable for components of most elastomers and plastics, whereas PTFE withstands temperatures as high as 260°C. Even below 77°C, if acids corrosive to metals and organic solvents are combined, liners and components of PTFE are often preferred because elastomers and other plastics often lack resistance to solvent swelling and softening.

Chemical Inertness

By Chemical inertness, we mean that PTFE fluorocarbon resins can be in continuous contact with another substance with no detectable chemical reaction taking place. In general, PTFE fluorocarbon resins are chemically inert. Nevertheless, this statement, like all generalizations, must be qualified if it is to be perfectly accurate. The qualification will not lead to confusion, however, if one keeps in mind the basic facts about the behavior of PTFE resins.

The usual description summary of various test data can be misleading, for it may lump together fundamentally different types of “Chemical” behavior. If the description is to be clear, it must distinguish between strictly chemical reactions and physical actions such as absorption. The description must enable the user to take into account the interrelationships of the physical and chemical properties which may affect a particular application.

For example, PTFE resins will be unaffected by immersion in aqua regia. Yet if the temperature and resultant pressure of this reagent become high, absorption of the components of the reagent into the resin will also increase. Subsequent fluctuations, such as sudden pressure loss, can then be physically damaging due to expansion of the vapors absorbed in the resin. Obviously, then, when we talk about the chemical properties of PTFE we must distinguish between strictly chemical reactions, as we expressed in terms of “Chemical compatibility” and physical actions, such as “absorption” combined with mechanical and thermal stress.

Within normal use temperatures, PTFE resins are attacked by so few chemicals rather than tabulate the chemicals with which they are compatible. These reactants are among the most violent oxidizers and reducing agents known. Elemental sodium in intimate contact with fluorocarbons removes fluorine from the polymer molecule. This reaction is widely used in anhydrous solutions to etch the surfaces of PTFE so that the resins can be adhesive bonded. The other alkali metals (potassium, lithium, etc.) react similarly.

In some instances at or near the suggested service limit temperature of 260°C for TFE & PFA, and 204°C for FEP, a few chemicals at high concentrations have been reported reactive toward PTFE. Attack similar to the sodium etch has been produced at such high temperatures by 80% NaOH or KOH, metal hydrides such as boranes (e.g., B2H6), aluminum chloride, ammonia (NH3), and certain amines (R-NH2) and imines (R = NH). Also, slow oxidative attack has been observed by 70% nitric acid under pressure at 250°C. Special testing is required when such extremes of reducing or oxidizing conditions are approached.

Absorption

In contrast to metals, plastic and elastomers absorb varying quantities of the materials they contact, especially organic liquids. Absorptivities in PTFE are unusually low, and a chemical reaction between the plastic and the other substances is a rarity (with the few exceptions noted previously). However, when absorption is combined with other effects, this property can influence the serviceability of these resins in a particular chemical environment. For example, if rapid fluctuations in temperature or pressure occur, circumstances may be created that are physically damaging. The wider service temperature range for PTFE resins exposes them to this type of physical damage more frequently that other plastics.

By way of explanation, let us consider the “steam cycle” test described in ATSM standards* for lined pipe. Samples of lined pipe are subjected to 0.8MPa (125 psi) steam, alternating with low pressure cold water, causing very severe thermal and pressure fluctuations indeed. This is repeated for 100 cycles. Steam created a pressure and temperature gradient through the liner causing absorption of a small quantity of steam which condenses to water within the liner wall. On pressure release, or on reintroduction of steam, the entrapped water can expand to vapor causing an original micro pore. The repeated pressure and thermal cycling enlarges the micro pores, ultimately causing visible water-filled blisters within the liner. The ASTM standards note that the blisters do not adversely affect pipe liner performance – the chemical barrier thickness is still intact.

There are corrosive measures which reduce the severity of blistering. Thermal insulation of a lined pipe or vessel reduces the temperature gradient in the liner, thereby often preventing condensation and subsequent expansion of absorbed fluids. It also reduced the speed and magnitude of temperature changes, thereby minimizing blistering. Thus, by reducing the resin, insulation can provide a protective measure in many cases. Additional protection can be provided by using operating procedures or devices which limit the rate of process pressure reductions or temperature increases.

Permeation

Permeation is a factor closely related to absorption, but it is also a function of other physical effects, such as diffusion and temperature. In over 20 years of experience with PTFE lined pipe, the number of failures attributed to permeation of a corrosive vapor followed by corrosion of the support member have been remarkably few. The liner thicknesses of 1.27 to 6.35mm necessary for physical strength at high temperatures reduce permeation to the point that it is normally a minor consideration. Because so many variables affect permeation, it is misleading to use laboratory permeability data obtained with thin polymer films as the basis for selection of specific fluoroplastic polymer linings. With few exceptions, differences in permeability among fluoroplastics have little bearing on performance of fabricated piping and equipment. Performance is controlled primarily by design, fabrication and quality control. Hence, the primary concern is usually with absorption, since this is the property most indicative of the serviceability of the fluorocarbon resins in a given chemical environment.

In unbounded linings, it is important that the space between liner and support member be vented to the atmosphere, not only to allow escape of minute quantity of permeant vapors but to prevent expansion of entrapped air from collapsing the liner. Also, these vents are used for quality control testing of lined pipe and as a safety device to indicate leakage in case of liner damage. Liner collapse is often attributed to permeation when in fact the primary cause is the occurrence of vacuum in the process stream. Manufacturers of lined pipe publish the resistance to vacuum at rated temperature of their different sizes and liner thicknesses, but it is sometimes necessary to prevent excessive vacuum by design features and operating procedures.

Post time: Feb-14-2019